Engineering & Design

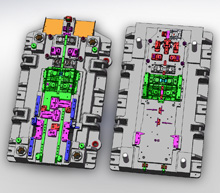

Anderdon Tool provides engineering and design of quality metal stamping dies. All die design requirements are handled in-house. Our ability to provide in-house design enhances communication between project managers, designers, engineering, tool makers, and end customers.

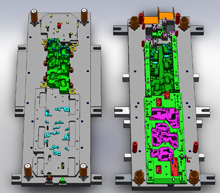

Our progressive die designers make use of die form simulation software to optimize material usage.

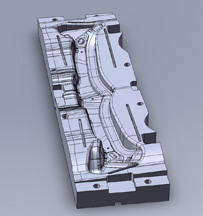

Dynaform die form simulation software is used on every project to help identify stress points, aid with the design of stage tooling, and determine optimum nesting of parts for best material usage.

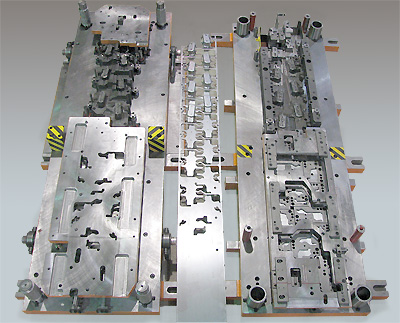

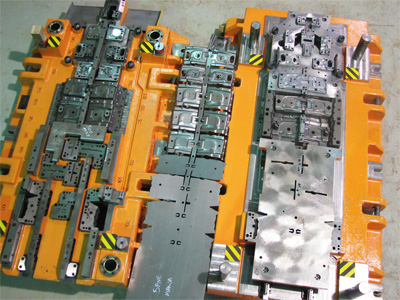

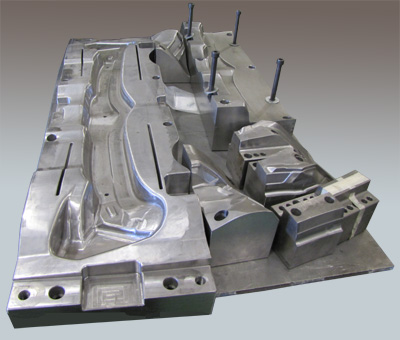

Complex Progressive Dies are a mainstay of Anderdon Tools' Die manufacturing.

Quality

Quality is a by-product of our die building process. From design and engineering through to manufacturing, assembly, and tryout, we rely on our process and people to deliver quality at every stage.

Run-off parts are inspected to your requirements. Complete reports are provided. Process capability studies are conducted using random samples from a continuous die run. Full part layouts are conducted on a minimum of 5 to 6 pieces. We have in-house CMM for full part layouts and inspection. Raw data and material certificates are available upon request.

Anderdon Machine Tool & Manufacturing is registered to ISO 9001:2008.

Engineering & Design Goals

Our design goal is to engineer tools to the following criteria:

- To your part geometry and material specifications

- For known material and coil variability (your material supplier)

- To fit your press (stroke, bolster size, tonnage, mechanical/hydraulic, controls)

- To utilize your press equipment (coil feeders, straighteners)

- For your new or existing automation

- For your plant and your die handling requirements (tonnage & dimension maximums)

- For your new or existing scrap handling and removal systems

- For low cost maintenance over the life of the tool

Although stage tooling is custom, Anderdon Tool relies on standard components, when available, to reduce design and manufacturing costs

We'll provide effective project management and communications to keep your project on-track, on-schedule, and on-budget. We will provide proactive communications to help you maintain your schedule and keep track of any outstanding issues.